So the guy I used to buy yarn from when I started making rope is no longer in business. I found this out when I contacted him to buy more yarn. He referred me to the guy that he had passed his jute mill contact information. I contacted that guy and bought yarn but he only had 3 of the 6 colors I needed plus a violet yarn in place of the purple. We talked and I told him I was interested in splitting the cost of his next order and he was very open to that idea saying it would allow him to order yarn a lot sooner. I checked back a few months later and he said that he was still interested. In the meantime, I ordered additional yarn on one or two occasions without any issues other than him being really slow to send an invoice and ship. After about 18 months from our original conversation, I sent an email saying I needed more yarn soon and simply asked what colors he had in stock. I didn’t bring up anything about splitting an order since he no longer seemed interested in discussing that. Well, that was in December and he never replied. In February of this year, I sent him a text message saying I needed to place an order. I sent a second text message the same day with the order information and asked him to send me an invoice. He never responded to the text messages.

At this point I’m in a situation where my supplier will no longer communicate with me so I cannot order the yarn needed to continue operating the business. Even if he does sell to me, he doesn’t have all of the colors that I’m out of nor the colors I want to add. With the yarn inventory running very low and popular colors depleted, I started looking for a new source for yarn. I’ve communicated with jute mills and brokers from both India and Bangladesh. There are significant difficulties with ordering directly from Asia. Many of the mills want to ship by the container load which is 12 to 15 metric tons (12,000 kg to 15,000 kg). At $1.80/kg, that’s a big investment and an overwhelming amount of yarn! Then comes the cost of shipping it which is between $8,000 and $10,000. Some sources, probably exporters or brokers, will ship smaller quantities but still in a sea container so the cost of shipping is way more than the cost of the yarn. An empty shipping container costs about as much as a full shipping container to ship! I need a way to ship smaller quantities without paying for a whole container. There are freight forwarders that can consolidate several smaller shipments into a single container and reduce the shipping costs of each order. I haven’t found a good source for that option yet but I’m continuing to look.

While researching in some forums, I found a possible yarn supplier in the United States and reached out to them but it was slow going and he passed me off to his partner. They were willing to sell me yarn at a really good price but the shipping seemed to be a huge obstacle. The last yarn I purchased cost me $16/kg after shipping. This source was asking $2.50/kg before shipping which should have been about $3.50/kg. So I was really excited about buying yarn at $6.00/kg after shipping! But the supplier was very very slow to respond to messages.

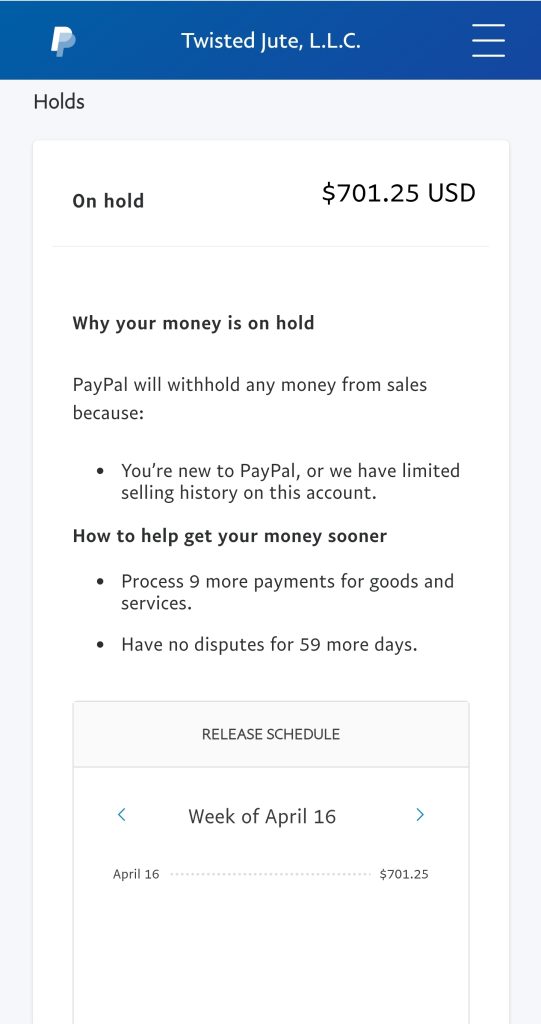

Finally, after a few days of not hearing from the supplier, I suggested I might be able to drive to Texas to pick up the yarn in person and I got an immediate and positive response for that idea. So, I arranged for travel and went down to Dallas, TX to buy yarn. I increased the original order total from 100kg to 250kg as this would lower my cost per kilogram by spreading the travel costs over a greater number of units. So, I spent $625.00 for 250kg of yarn and another $816.00 on travel expenses including car rental, lodging, fuel, and food. The grand total for the trip and yarn was $1,441.00 which means the yarn ended up costing $5.90/kg! That’s way better than the $16.00/kg I paid last time for much better quality yarn.

The downside is that none of the yarn is colored so I will need to color match and dye yarn myself. I’ve began researching the process I’ll need to follow in order to dye my own yarn. It adds a step but given the overall cost savings, it is a good trade. Additionally on the trip, the supplier provided valuable information about importing yarn from India directly which could result in lower costs and fewer supply shortages.

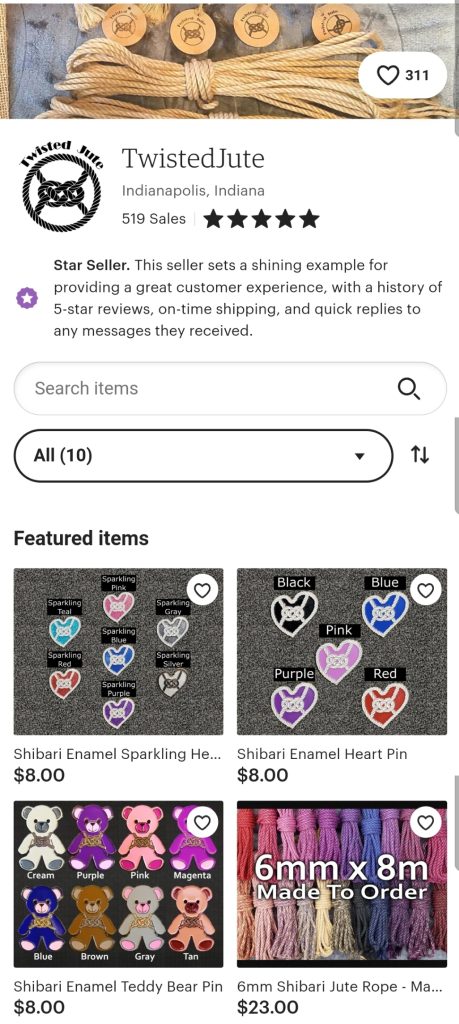

I’ll be opening a second Etsy shop soon which will offer unprocessed natural rope at a very competitive price. The shop will not be linked to the original shop so customers will not know they are the same owners. This will allow us to sell inexpensive rope in larger quantities which will provide better positive cash flow without lowering the premium expectations of the original shop. We don’t want people to question the premium prices for our premium products by directly offering a budget product in the same shop. Basically, we’ll be offering a generic line of products through the second shop. This would be the same as the grocery store brand of canned fruit coming from the same supplier of the brand name canned fruit. The only difference is basically the label on the can or in our situation, the label on the rope.