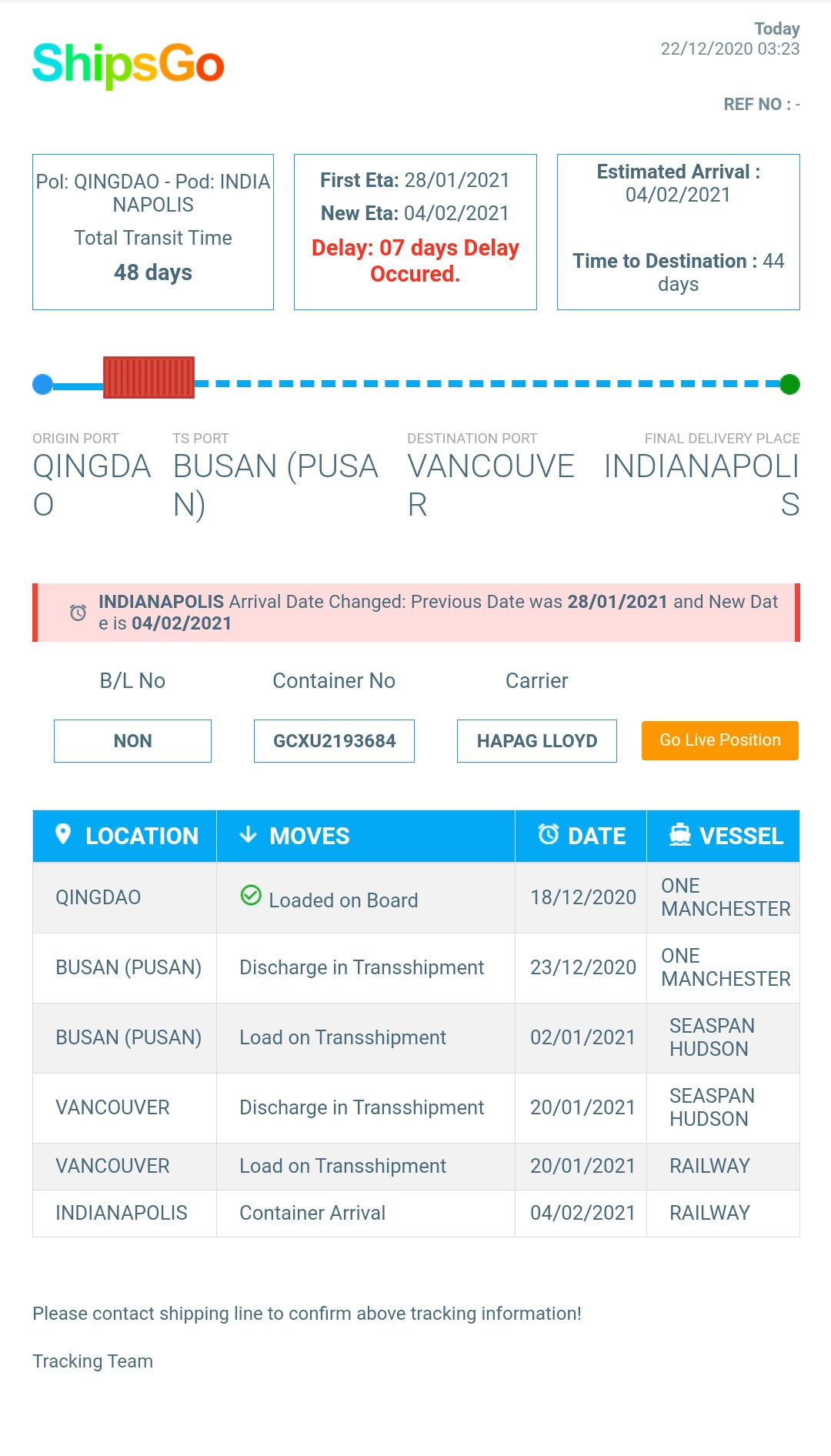

The overhead door header wasn’t very adequate and it allowed the head of the door jam to sag about 1/2 inch. The header was just a 2×6 board that was held in place by only 7 nails. I replaced that with a 2×10 that rests on the door jams and nailed it into place with about 30 nails and flipped the old header over so the sag was a crown and nailed it to the new header with about 20 nails to add additional support to the header which has removed the sag that was present before. You can see the difference between the two blue lines of the before and after.

Once the header was done and the sag removed I lowered the door opener several inches to allow enough space to put insulation over the mechanism. The opener still needs to be adjusted a bit to allow enough clearance between the opener linkage and the joists.

These adjustments should allow for adequate height clearance for the machine to fit through the door opening.