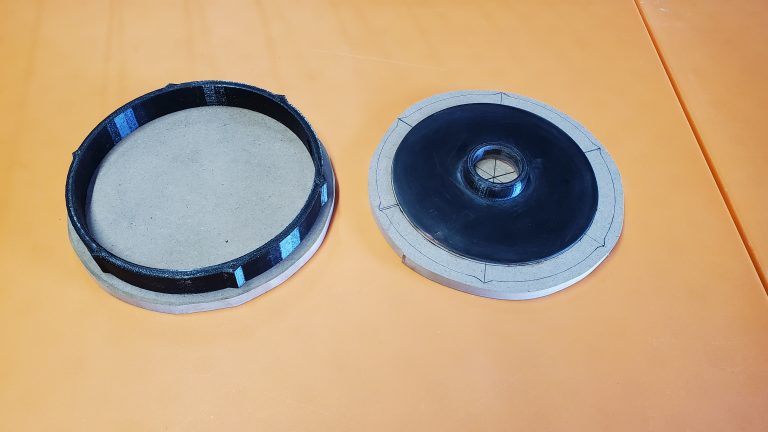

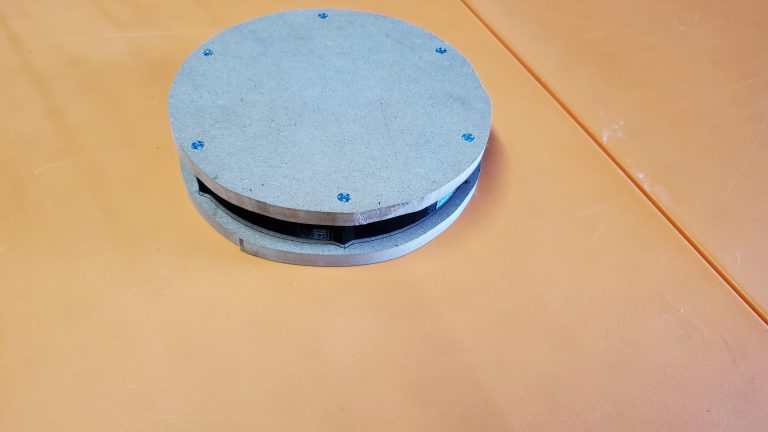

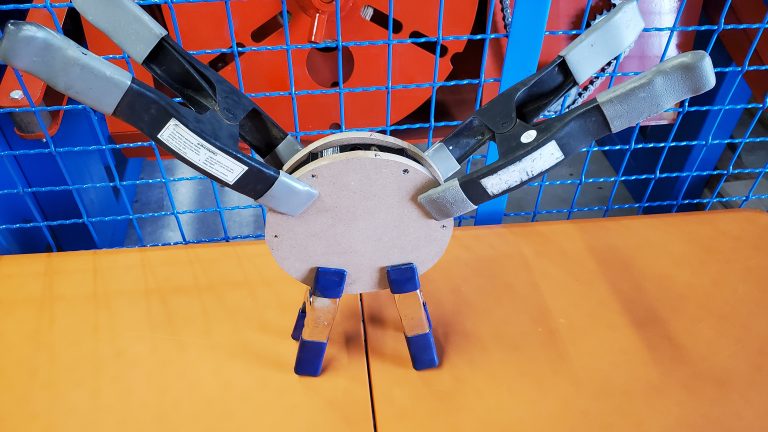

So today I went to the workshop and uncovered the three new molds I poured yesterday. For the most part they turned out well. I cleaned and dried them then prepared to cast new flanges. Using rough math I was able to calculate the approximate volume of each flange to be cast as 1.65oz. I have four moths so that came out to 6.6oz of epoxy that needed to be mixed. I added black pigment to the resin and started to mix. Soon after starting to pour the mixed resin into the molds I realized that the table was not level and the resin was all flowing towards the low end. I finished the pour and repositioned the mold to be level. I used the heat gun to remove as many bubbles as possible.

So I had about 2oz of resin left which makes each flange about 1.2oz instead of 1.65. I’ll be able to mix a closer amount next time. It takes 24 hours for the resin to cure so that gives me time to print flanges on the 3D printer.

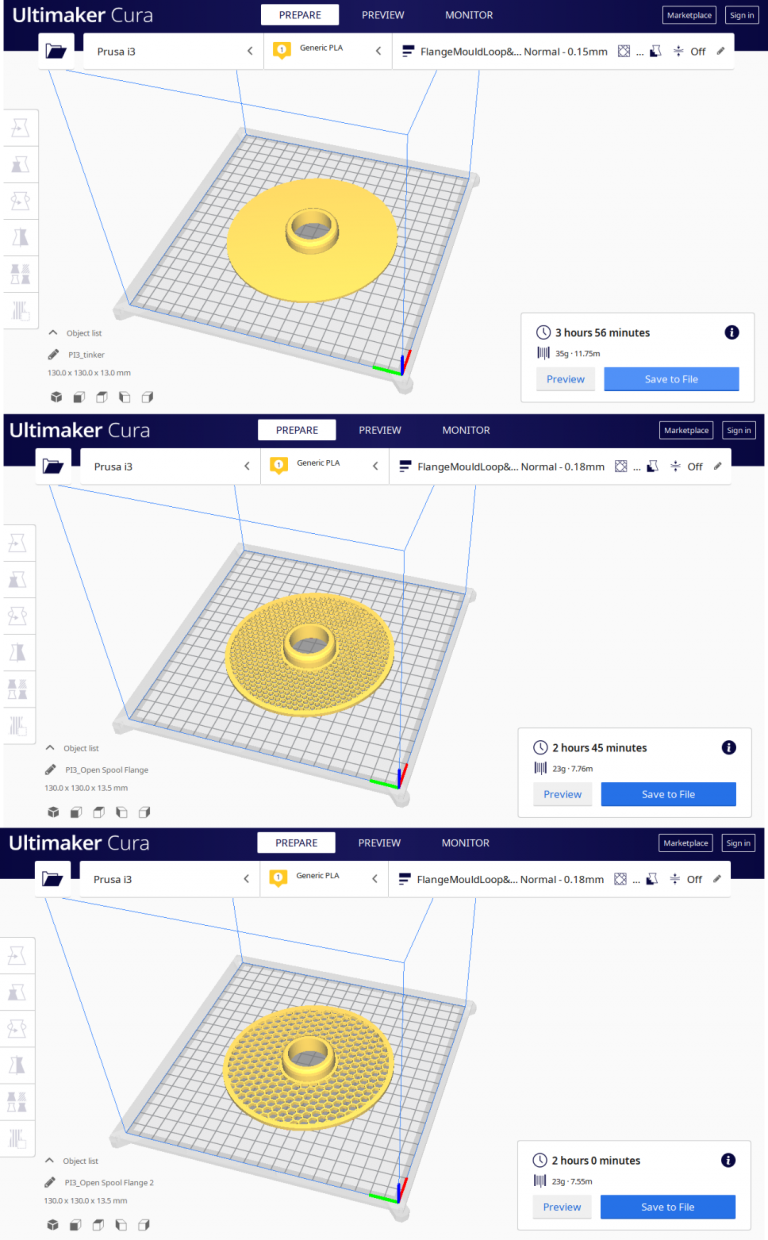

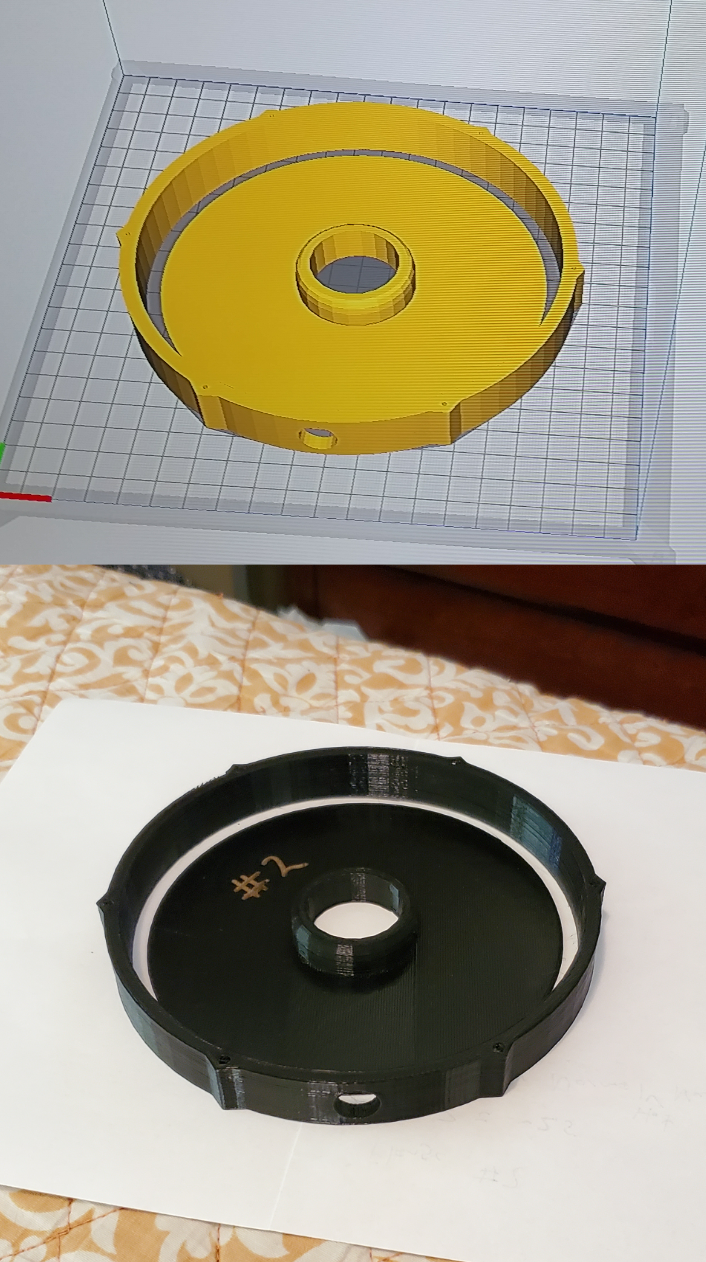

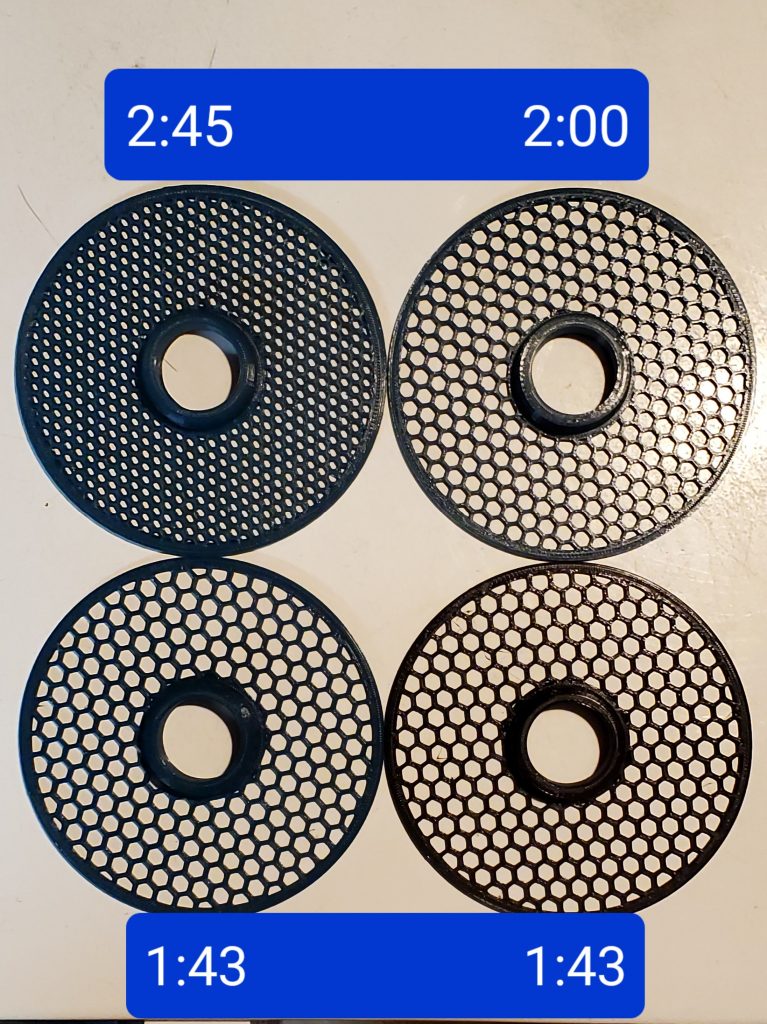

The original solid surface flange I used to make molds out of takes 3:56! That’s fine for casting but I need to speed up the print time so I can get to my goal faster. So I designed a flange that uses an open honeycomb grid on the flat side. It takes 2:45 to print. I redesigned it with larger hexagons and got the print time down to 2:00! With a little more tweaking I got the print time down to 1:43. So my Theoretical printed flange production rate is 13 per day. Of course sleep and work bring that number closer to 5/day. So 5 printed and 4 cast gets me 9 flanges a day so I could have my minimum required flanges in about 6 days.

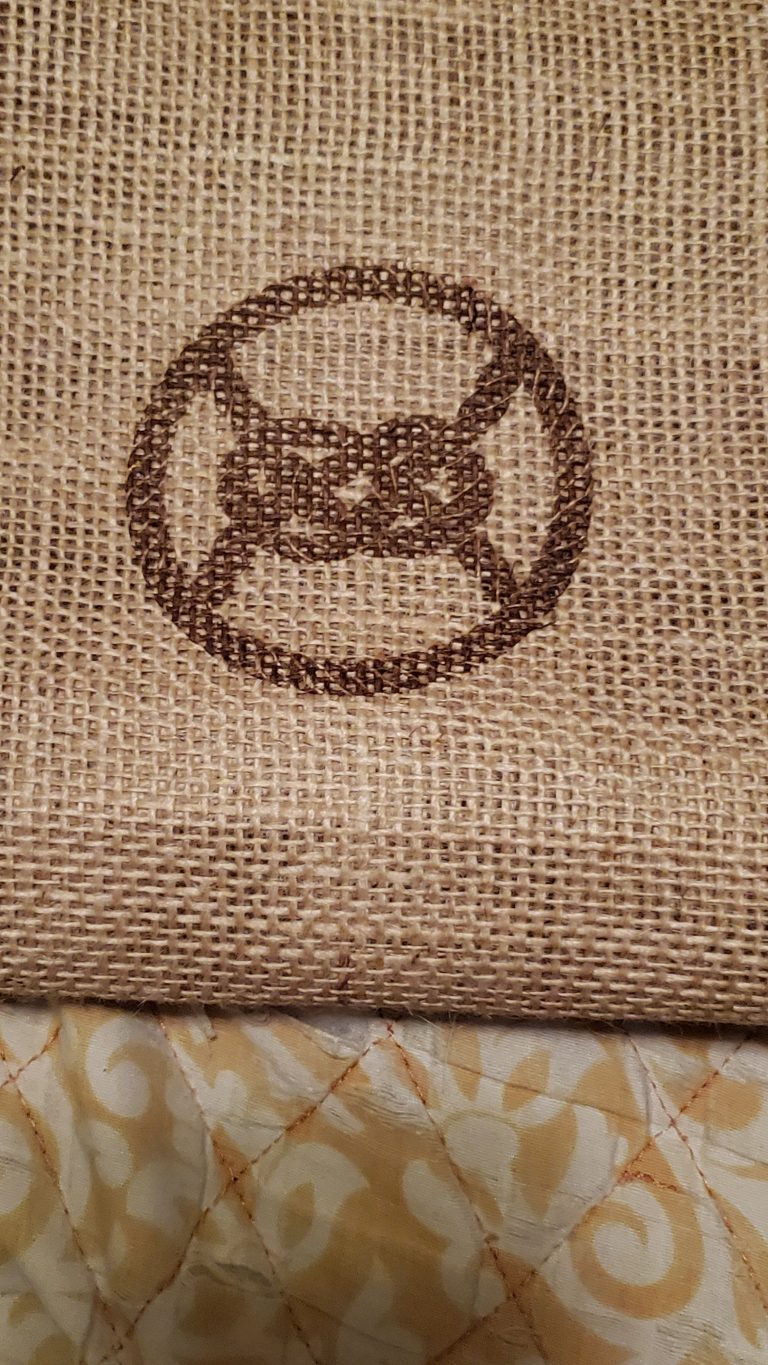

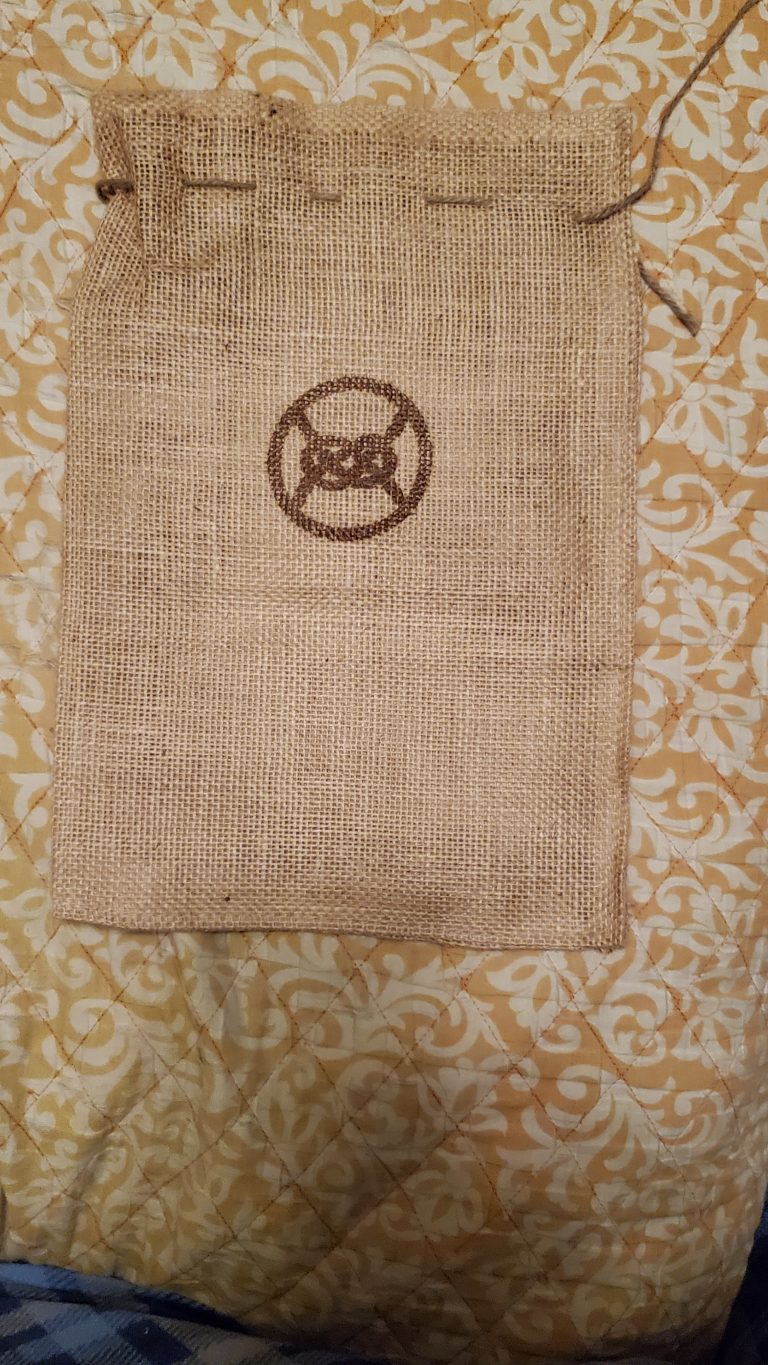

Ever since I started considering using burlap bags as shipping material for rope I’ve wanted to get the company logo on the bag. Today I tried using the laser engraver for that purpose.

So the burlap is just a bit too loosely woven to get all the detail to show but you can definitely identify the logo. Unfortunately the logo isn’t very big and the process takes a long time so I may need to reevaluate that.