So the yarn from the big 5kg spools has to be transferred to smaller spools to run through the rope machine. Mostly this is because the machine can handle 24 spools at a time but 6mm rope requires up to 54 spools. Besides the capacity issues of the machine, 24 full sized spools at 11lbs each is a lot to deal with. So smaller spools will need to be used with multiple threads per spool.

The problem is that the tubes don’t have flanges which limits how much yarn they can hold and creates a situation where the yarn can slip off the spool and get tangled on the spindle. So I need 2 flanges for every spool I use…

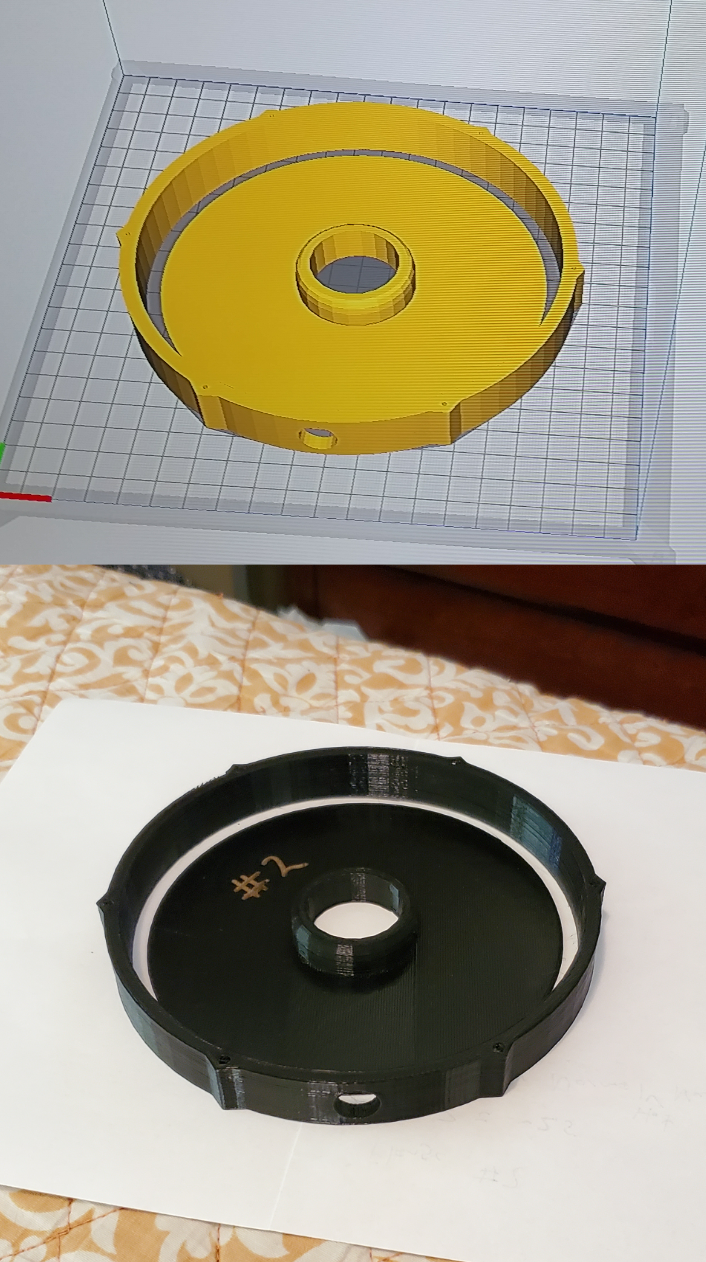

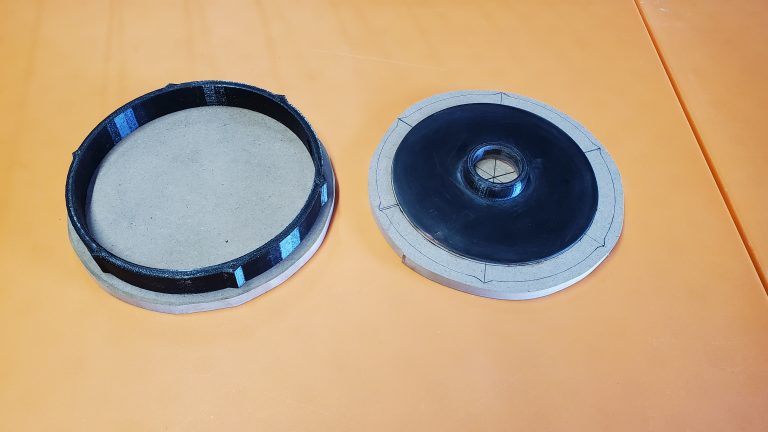

So I have a 3D printer that can print prototypes that I can then make molds from so I can cast flanges out of epoxy resin. Well that had a few hiccups. The printer had a few fails before it did a near flawless print of a flange and a frame for the mold…

The next print went more like this.

Then the extruder stopped working entirely. Had to replace the extruder motor and cable. Days wasted trying to fix, troubleshooting, and waiting for a replacement motor…

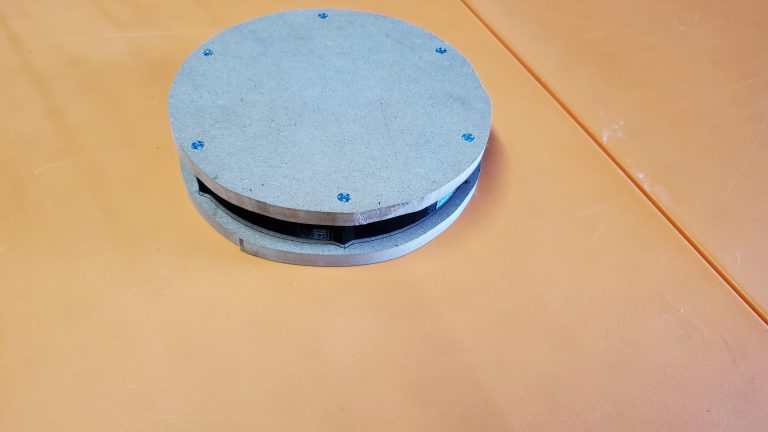

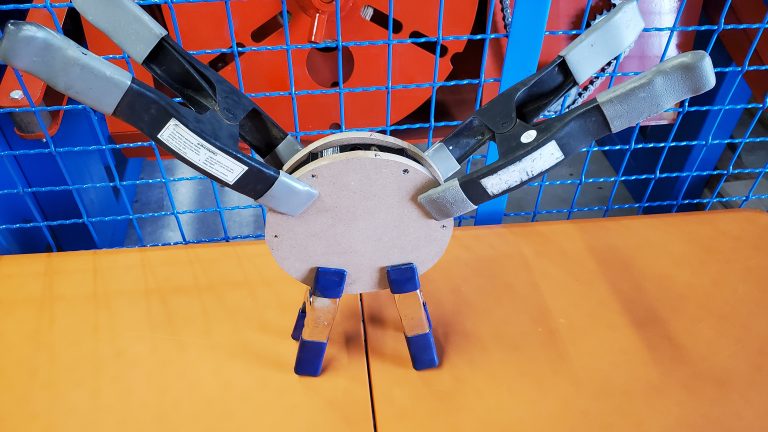

While waiting I went ahead and put together one form and filled it with silicone to make a reusable mold.

It was a little messier than expected and a lot wasted but overall my volume calculations were correct for the amount of mold maker to mix. Should find out today if I have a new reusable mold or a silicone paperweight.