So the test yarn is spooled and loaded into the rope machine. Learned the basic operation of the counter module which shuts the machine off when it reaches a specified number of revolutions. Once the machine is ready for production I can calculate the volume of rope made per revolution. This is approximately 2 inches per revolution. So I can set the counter to stop once the machine has made the amount of rope I need.

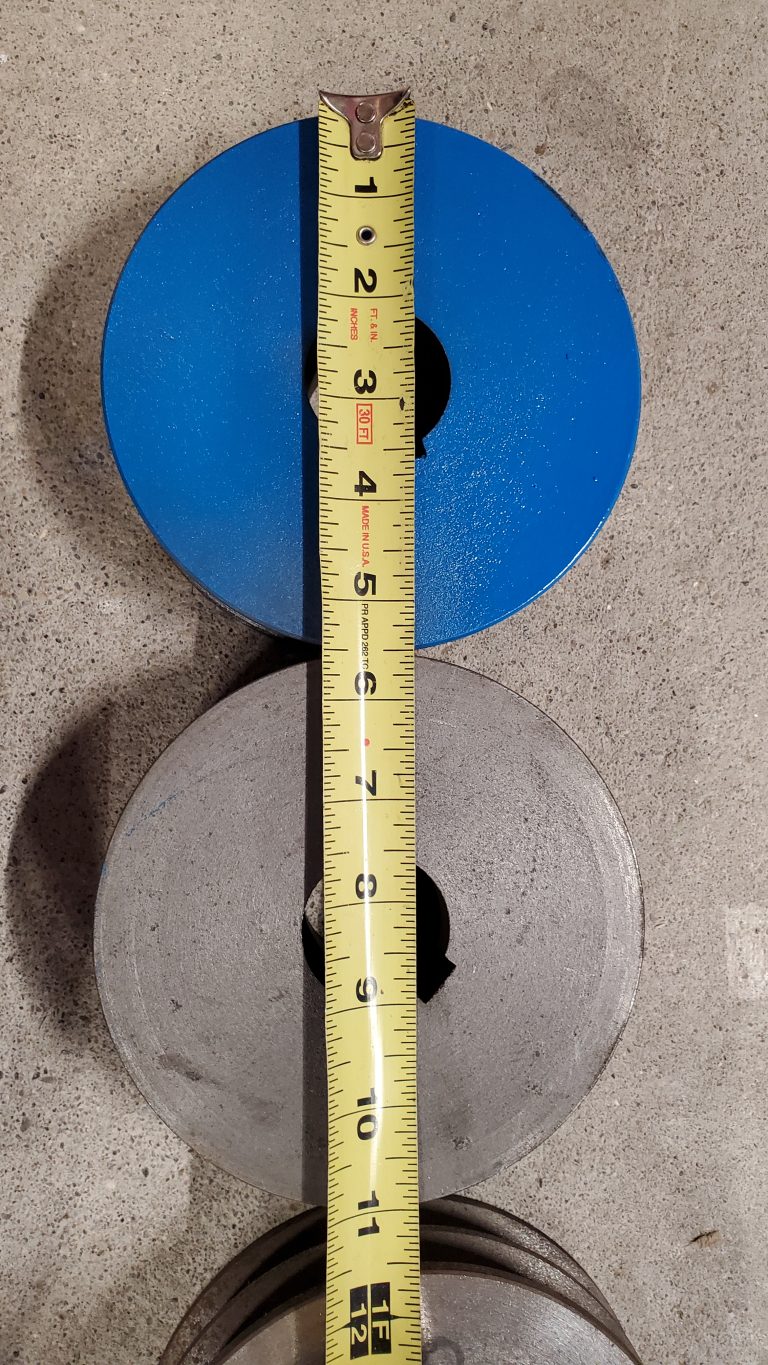

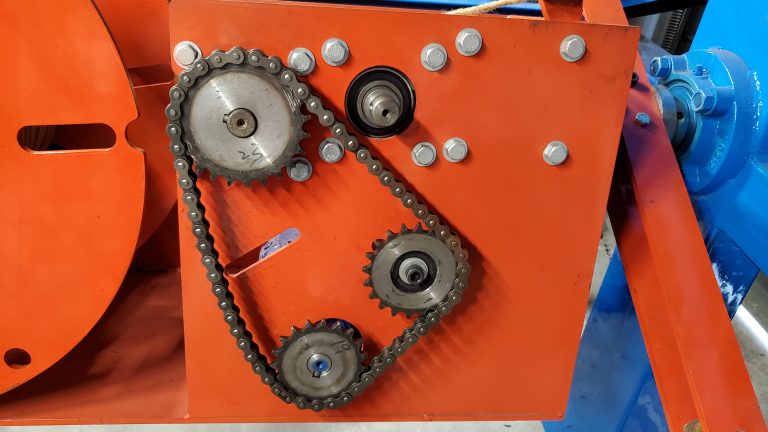

I started swapping the belt pulleys and chain sprockets to produce rope that has the same twist and feel of the rope I make by hand.

I ran hundreds of feet of rope through the machine trying to get the pulley and sprocket ratios just right. I eventually ran out of yarn before I could get to where I wanted to be. The rope looks good despite not having been screened for contaminants before being twisted. The twist is also very close to the desired parameters.

Onice I get more yarn spooled and loaded into the machine I shouldbe able to get it dialed in pretty quickly. Lol, like maybe a day.

I believe I have enough yarn on hand to make 100m (12.5 hanks) of every color combination the shop offers.

The next big step is to design and build a machine that will wind several spools of yarn at once while the yarn can be inspected, repaired, and cleaned. Currently I inspect about 1800 feet in about 8 minutes or 225ft/min. I’d like to significantly increase that rate but definitely cannot fall below that rate. At the lowest speed the machine can turn yarn into rope about 2.5 times faster than I currently can inspect it. So even if I significantly improve the inspection and spooling rate the machine will almost always be waiting for more yarn.