Transportation

it seems that transporting the container from the rail yard to the workshop isn’t an easy or straightforward task. To begin with you really only have one option for having the container picked up at the rail yard. Next, that company will only take the container to a commercial address. Third, you gotta have a way to unload the machine and transport the contents to the workshop. Fourth, every day you don’t get this accomplished costs hundreds of dollars.

Setup

So just to get the machine fully into the workshop I had to lift it and set it on 6 furniture dollies then still had to us a 5′ pry bar to slowly nudge it into place.

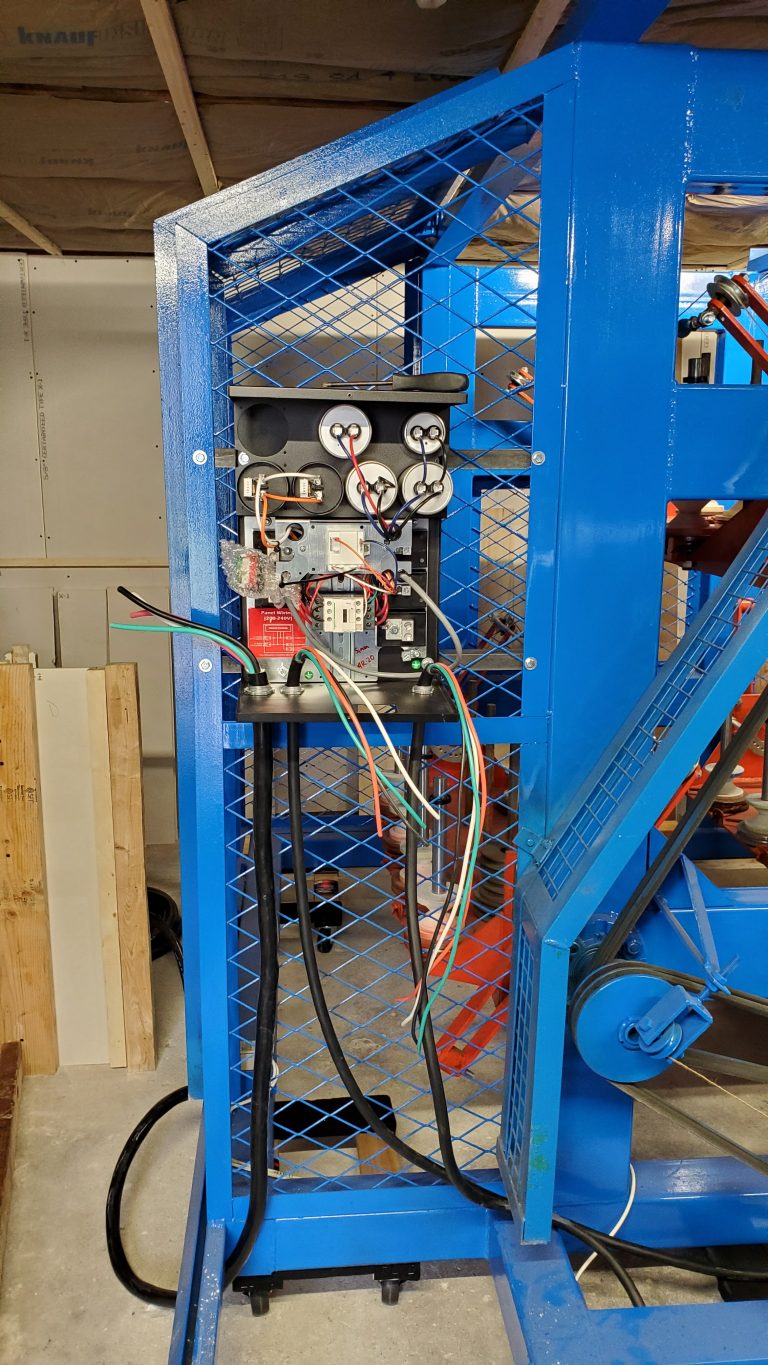

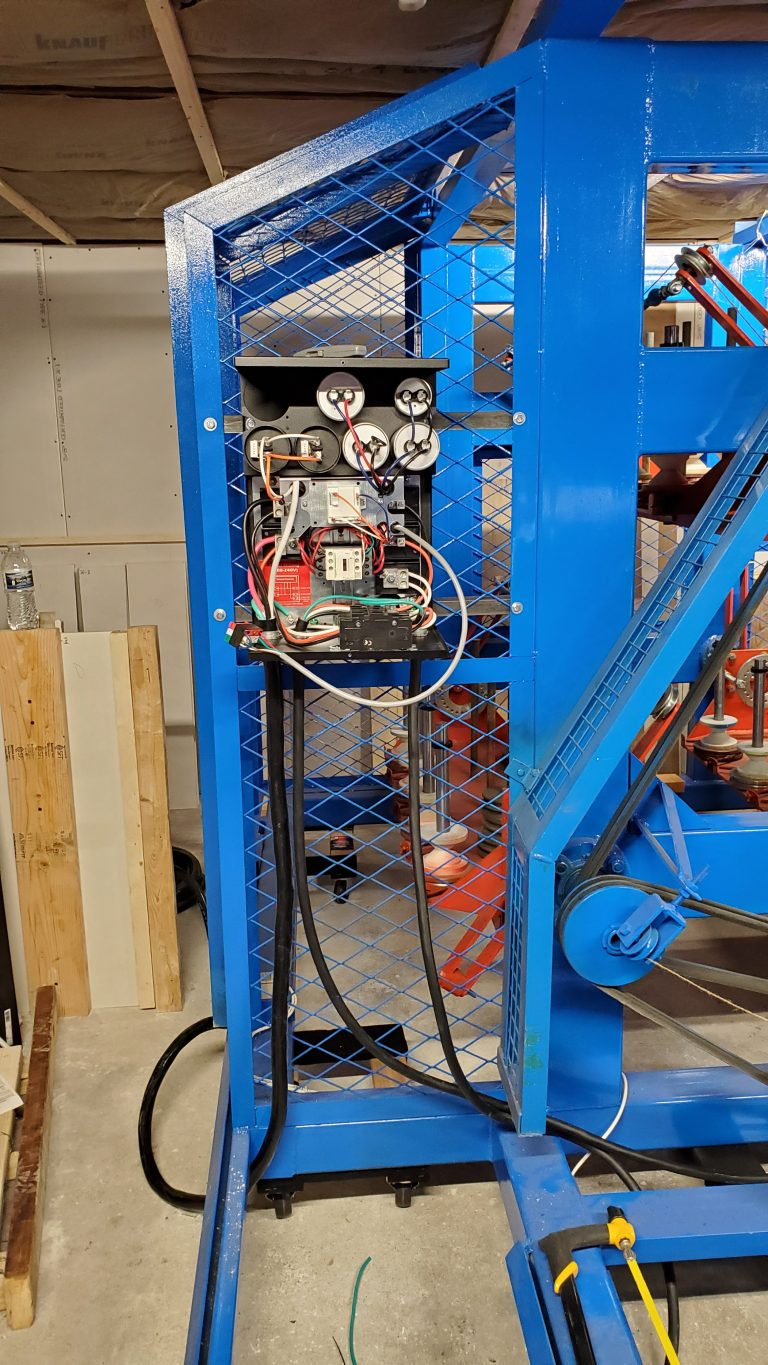

Next step is to connect the power. This sounds easy enough but it’s pretty complicated. The workshop doesn’t have the right power requirements so I need to use a large generator and a converter to change to power into the kind the rope machine can use. I decided to mount the converter to the machine. The converter comes as two parts; the control panel and the idler motor. The panel will be mounted on the large cage near the machine controls and the idler motor will be mounted on the other side near the floor.

Today I was able to add mounting brackets, attach the control panel to the cage, run the 50 amp and 30 amp power cords to the control panel and to the machine as well as run the line for the idler motor, and wire the control panel.

Next, I need to mark the power connections with appropriately colored electrical tape, bundle wires together with zip ties, terminate the unused neutral wire from the generator, attach cable clamps to secure the cords to the frame of the machine, move the open power connections on the rope machine into an electrical junction box, mount the idler motor to the machine frame, and wire the idler motor.

Bought some jute twine to run through the machine to learn how it works…